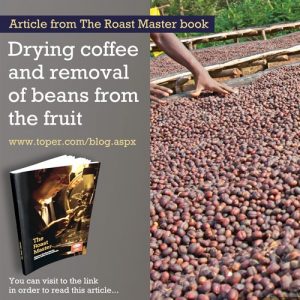

Following picking, the red ripe coffee cherries are dried and the green beans are removed from the fruit with several methods. These methods vary depending on the coffee plantation size, the producer’s conditions and the climate of the region.

Sun-drying and its effects

Sun-drying method is used to dry the red ripe coffee cherries on the trees, plantations or special conveyers.

Drying lasts for weeks depending on the climate conditions. The green beans are removed once the cherries are fully dried.

Washing sun-dried cherries may result in lower acidity and strong taste depending on the washing method.

Wet processing and its effects

Wet processing is a method of drying the red ripe coffee cherries through the following steps which respectively are:

1. De-pulping cherries (red or yellow) to remove the parchment,

2. Removing mucilage through fermentation or mechanical process,

3. Washing the beans to remove the fruity material,

4. Drying the beans with their parchment. Machine-drying takes 1 or 2 days while sun-drying does 3 to 16.

Wet processing results in cleaner, higher acid, and consistent, and generally more expensive coffee compared to natural drying. Wet processed coffee beans are denser and require more aggressive roasting.

Semi-washed processing and its effects

Semi-washed method of coffee processing involves de-pulping cherries, and allowing the beans to dry with most of the mucilage untouched. This process results in sweet and clean coffee.

This method is mostly preferred in dry regions for it does not require water unlike wet processing. Coffee beans, naturally processed with semi-washed method, also require less heat and gas level for they are easily roasted.